Solar panel production line

10MW solar panel production line

Please watch the video on Youtube:

https://youtu.be/JFjij2QcQpI

Module type Glass-Backsheet module, Glass-Glass module

Max size of solar module2094 x 1038 mm Mono and Poly.

Busbar 5 BB - 12BB

Production speed: 216 pcs solar panel ( 2094 x 1038 mm, 455W)per 24 hours .

Daily working hours 24 hours

Yearlty working days 300 days

Facillity condition

Producetion space˃ 1000 m2

Operators per shift ˃ 12

Power supply requirement: 380V- 400V , 3 Phase 5 wires. or customized

Power consume Max 100KW

Air supply requirement Copressed air 0.5 ~ 0.7 MPa . 200 L / min

Water Do not need .

Temperature 25 ℃

Humidity 50 % - 70 %

Technical Specifications of machine

Specification of machines

1, Solar cell tester

Model : GCT - B

Model : GCT - B

Apply to the test and result record of mono-Si or poly-Si solar cell pieces.

Can test 6 - 12BB mono and poly cell .

158 - 210 mm solar cell .

Pneumatic and buffering contact, front probe contact, back contact;

Four-line survey; 10 parameters display; 8,000 data collecting dots;

Irradiance automatically compensating;

Temperature automatically compensating;

Measurement parameter displays in tabulation and graphic way;

Voice counts off and prompts;

Counting prompt of flash times;

24hrs continuous working;

Working life of imported Xenon lamp is 300, 000 times of flash

Technical parameters:

Model | GTC-3A | GTC-B |

Lamp Spectrum | In line with iec60904-9 spectral Irradiance distribution requirement(AM1.5) | |

Light intensity | 100mW/cm2 (continuous adjustable range 70-120W/cm2) | |

Spectrum matching (400-1100)nm | 6.2% | |

Test result consistency | ≤±2% | |

Test error of electrical properties | ≤±2% | |

Single flash time | 10 ms | |

Effective Test range | 200x200mm | |

Measuring votage | 0~0.8V(resolution 1mV) | |

Measuring current | 0~20A(resolution 1mA) | |

Test Parameters | 1sc, Voc, Pmax, Vm, Im, FF, EFF, Temp, Rs, Rsh | |

2,Laser cutting machine

Model : RO - 2100F

High speed, 1600 / h

Be used for cutting solar cell 158 x 158,M6 ( 166 X 166 ), M10 ( 182 X 182 ). M12 ( 210 X 210 ).

Loading : Whole cell box , 100pcs.

Unloading: Whole cell box.

Not pollute on solar cell.

Power of laser: 30W. 10% to 100% variable.

Laser wave length: 1064nm

Dicing speed : Maximum: 600mm/s

Deepness: 1/2 - 1/3 cell.

Precision : +/- 0.05mm

Frequency : 20 - 80KHz variable.

Air pressure: 0.6 - 0.8 Mpa. 400L/min

Power: 220V/50Hz, 2 KW

Measurement: 1250 x 1100 x 1380mm

Net Weight: 300Kg.

3, Solar cell soldering station

![]()

Model: H2020E

H2020E is a single track automatic tabbing and string for solar cells

Up to speed 1800 cells/hour.

High flexibility for 5BB/6BB/9BB/12BB solar cells .

The base solution is 3 type of cell of 210x 105mm, 182 x 91mm, 166x 166mm and others .

Works with different kind of cells including cut cells with width >30mm

The number of cells for string is settable from touch screen

Cell spacing is adjustable

Quick and simple operation & ribbon change

Low cost of spare parts and consumables

Soldering capacity | Max 2.7 seconds /pcs,Max1800 pcs /hour |

Cell‘s dimension | 30~166*210mm |

Cell busbar | 5BB/6BB/9BB/12BB/ |

Ribbon sizes | Width: 0.8~2.0mm,Thickness: 0.12~0.23mm . Ribbon size should be informed before order |

Breakage | ≤0.2%, On the basis of Grade A cells with good cutting, no cracks and damage |

Cell basket capacity | 4 x 100 PCS,4 Cell baskets to load up to a maximum 100pcs each,total 400pcs auto switch |

Operation control | PLC touch screen |

Soldering technology | IR light |

Soldering light life | ≥1000Hr |

Soldering temperature | Normal~400℃(adjustable) |

Input power | 3 phase/50~60Hz/380V/30A, Power cable >6mm2 |

Peak power | 18 KW |

Average power | 7 KW |

Compressed air | ≥ 0. 5 Mpa clean & dry air |

Compressed air consumption | Approx 200L/min |

Max.length of the string | 2050mm, Suitable for 12pcs 6 inch cells per string with 2mm cell spacing |

Operator interface | English |

Warranty | 12 Months |

Local installation: Buyer pay for round flight ticket, accommodation . One engineer. More than 5 days. We will supply video call for installation in outbreak of infectious.

Machine size: 5040 x 1500 x 2000mm.

Operating space: 7000X 3000 mm .

4, EVA / BACKSHEET cutting machine

Model : RO - ECJ

Used to cut EVA and Back sheet into designed size for solar module manufacturing..

With Electric knife and pneumatic punching system.

Material: Aluminum alloy.

Device characteristics:

1, It can cut EVA and TPT for ,maximum 600 Wp solar panel.

2, Electrical cutter, High speed.

3, Easy to adjust the size.

We can customized make it according customer’s special need power supply : 1 KW single phase.

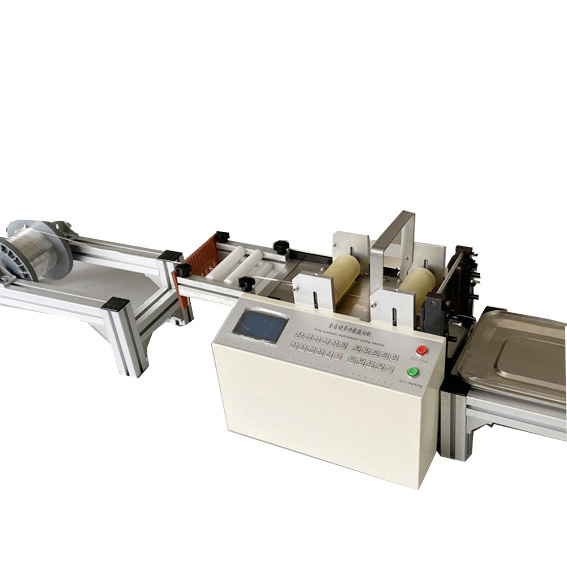

5, Ribbon cutting machine

RO - CJJ01

Full automatic. High speed.

Digital display.

Automatic alarm.

Cut length accuracy.

Speed and high efficiency.

The material of welding strip: Tinned copper alloy;

Straightening: 98%;

Cutting accuracy: L + _ 0.2 +0.002 L

Cutting Length :1-9999 .9 mm

Maximum soldering ribbon width size: 8 * 0.2mm;

Processing speed (colleague processing section 1-5): 350/minutes;

Power: 220V 50Hz

Power: Max 250W, minimum 20W;

Volume: 395 * 265 * 355mm

Weight: 26kg.

Video :www.youtube.com/watch?v=5ZN_ZZEfLYs

6, Laying machine

Use whole servo closed loop control

Adopt vacuum check technology

Servo lateral locating,digital locating.Set location distance just on the upper computer,be capable of setting every lateral locating distance separately,high efficient in servo location.

Spinning part adopts electronic control and cooperates with robot joint reducer(back interval less than 1arc.min).Be capable of setting spinning degree randomly(set by upper computer) and setting each string’s spinning angle separately.

Glass location device is hand wheel type and intensifying type.The time to change glass is short and no need to use other tools like wrench.

6 opening system and reserving about 30 percent hardware interfaces,which is convenient to the interface control of equipment and auxiliary devices.

ITEM | Specification |

Working voltage | AC380V,3 Phase 5 Lines,50Hz |

Rated power | 7KW |

Working air pressure | 0.5-0.8Mpa |

Average Air Consumption | ≧600L/min |

Driving mode | Servo driving |

Positional accuracy of cell strings | ±0.3mm |

Tact | 60s |

Interval of cell strings | 1~10mm(adjustable) |

QTY of cell strings | 4~12strings(adjustable) |

Switching time | ≦15min |

Breakage rate | ≦0.3% |

Cell main grid line number | 2-5grids,switching time≦30min |

Applicable Module Size | L(1600-2300mm)*W(800*1200mm) |

Material of transmission belt and sucker | PU |

Overall Dimensions | 2470mm*4180mm*2800mm(L*W*H) |

Total weight | About 2500kg |

Control system | Screen(MCGS),Chinese/English mode,supporting remote maintenance,and connection to local production-management software. |

Operating mode | Manual/Automatic |

Equipment Function: Cell strings laying up machine, working with Stringer by 1 VS 1, or 1 VS 2. Cell strings are in parallel with the long side of the modules after conveyed in the Automatic Layup Machine,and adjusted mechanically and by CCD. | |

7 , EL tester

RO- EL240B

Parameter

Product name | Semi-automatic El Tester | |

Resolution | 24 million pixels | |

Clear imaging time | 1-30s | |

Test cycle | 35s(before laminate) | 30s(after laminate) |

Detector type | Cooling type(-50℃) | |

Image surface noise | No | |

Software | Images automatically saved, statistics, query and print | |

Detection of defect types | Processes pollution, material defects, cracked, debris, broken gate, missing solder, low efficiency. | |

Test type | Solar module | |

Test size | Max.:2300mmx1200mm | |

Machine size | 2860 x 2200mm x 900mm | |

Test voltage | 0~10A 0~100V | |

Working environment | +15℃~+40℃(Temperature) 20~60﹪(Humidity) | |

Equipment placement environment | +5℃~+40℃(Temperature) 5~ 85﹪(Humidity) | |

8, Laminating machine

Model: RO-Q1 3600*2200

USE : As the equipment of manufacturing solar module limited to laminate glass, EVA (Ethylene Vinyl Acetate Sheet), solar cell and back sheet

Dimension : 14600 mmx 3380mmx1300mm

Laminating area: 3600mm x 2200mm. Laminating height: 25mm

Total power consumption: 80 KW ( AC380V, 60 Hz, or according to customer's nee)

Air source: 0.6 - 1.0 MPa.

Operating mode: Manual / Automatic.

Control system : PLC ( Siemens). HIM system: Touch screen .

Heating mode: Oil Heating ( SD320 heat-conducting oil, capacity: 170 L, flow pressure:0.3 Mpa.), inculde: main heating and adjustable heating.

Temperature control: PID intelligent temperature contol system.

Temperature uniformity in working area: ≤ ±1.5 ℃

Temperature control accuracy:≤± 1 ℃.

Temperature control range: 30℃ - 180 ℃

Pumping rate: 70 L/s .Laminating time: 2 - 4 mins ( Excluding sollidification time )

Heating rate: 135℃ at room temperature with 50 to 60 minutes

Vacuum rate: 200 L / S, the limit vacuum 70 ~ 90 Pa, vacuum Time: 90 seconds

Silicone sheet size: 4200mm * 2600mm, 5mm thickness. It will be changed after 3000 times.

Lid opening: Straight from the hydraulic, the biggest opening height: 200 mm

Total weight: 12.5 T

Production capacity:

Conventional 450 Wp ( 2094 * 1038 mm ) Module, 3 pcs at the same time .

Production Capacity: 450 WP * 3 pcs/ cycle * 3 cycles/h*8hours*300days=9.72 MWp/ year.

9, Trimming station

Model : RO - XBT

Be use to trimming the EVA and Backsheet out glass after laminating .

Automatic conveyor.

Trimming by electricity blade .

Can produce the maximum 600W solar panel 2400 x1200 mm and others .

10, Framing machine

Model: RO - ZKJ

The machine should be suitable to use for fix solar panel frame and lock the fourcorner of the frame.

Maximum panel size: 2500X1400mm or customized .

Power supply: single phase.

Loading system: Conveyor .

Difference of diagonal line difference:1.5mm.

With pneumatic gluing gun.

11, JB gluing machine

Be used to inject silicon gel for sealing junction box.

Full automatic control,

Advanced stepper motor with braker.

X/Y/Z Working range 300x300mm

ZY/Z Maximum load 10kg/3kg

XY/Z Speed 800/350mm/Axis

Transmission Precision micro - stepper motor

Dimession : 500x580x610mm

Weight 34 Kgs

12, Solar module tester

Model: GTM - B

Mainly used in electrical performance auto test and result record of solar mono and poly module.

A grade spectrum; A or B grade unevenness degree of irradiance;

Can beused for 210 cell and PERC cell solar panel .

A or B grade instability of irradiance;

Flash pulse 10ms, continuous adjustable;

Four-line survey; 10 parameters display;

8,000 data collecting dots;

Irradiance automatically compensating;

Temperature automatically compensating; measurement parameter displays in tabulation and graphic way;

Voice counts off and prompts;

Counting prompt of flash times;

24hrs continuous working;

Working life of imported xenon lamp is 300, 000 times of flash

Model | GTM-3A | GTM -B |

Lamp Spectrum | In line with IEC60904-9 spectral Irradiance distribution requirement(AM1.5) | |

Light intensity | 100mW/cm2 (continuous adjustable range 70-120W/cm2) | |

Spectrum matching (400-1100)nm | 6.2% | |

Test result consistency | ≤±2 % | |

Test error of electrical properties | ≤±2% | |

Single flash time | 10ms | |

Effective Test range | 2200x1100/5W~450W or customized . | |

Measuring votage | 0~100V( Resolution 1mV) | |

Measuring current | 0~20A( Resolution 1mA) | |

Interval time between tests | ≧ 7 seconds | |

Test Parameters | 1sc, Voc, Pmax, Vm, Im, FF, EFF, Temp, Rs, Rsh | |

13, Module transfer carrier

Model: RO - DZ

Hand truck for transportation of Glass / Modules / Panel at different stage of production.

The module carrier made of steel and continues welding with rubber combination.

It should carry 10 sets of 600W solar panels at one time & strong mobile castors for free and smooth movement during transport of modules / panels.

The wheels can be locked for safety and stability to avoid any accidental damage.

Support 10 pcs of 600W modules each time

14, Ready material carrier

Model: RO - DY

Hand truck for transporting the finished laying up module to be laminated, carry 10 pcs600W solar panel with proper protection.

15, Working table

Model: RO - GZT

Working table for select out solar cells from the faulty one.

And classification the solar cell for solar production.

Dimension :1200X1200X800mm

15, Compressor.

Model : AT-100

Model | Tank Capacity (L) | Air Dlivery (L/min) | Motor Power (W) | Speed (r.p.m) | Max Pressure (Psi) | Piston |

AT-200 | 56 | 100 | 1500 | 1050 | 115 | Ø51x2 |

Working Pressure:8 bar

Machinery Test Report:Provided

Core Components:Pressure vessel, Pump

After Warranty Service:Video technical support

Cooling method: Piston air compressors hp 5 with Air Cooling

Motor:air compressors with Copper motor

Compressor type:Min piston air compressors hp5

Warranty:1 Year

Power: 5.5KW / Voltage:380V

Dimension(L*W*H):159* 59 *98cm

Weight:155

1 X 40FT Flat rack --- Laminator

1 x 20ft container --- Tabbing and String machine

2 x 40ft container --- Other machines .

We customized design and manufacture solar panel machines according customer needs.

Such as building, work people and other condition.

Categories

News

Contact Us

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV