Solar panel machines

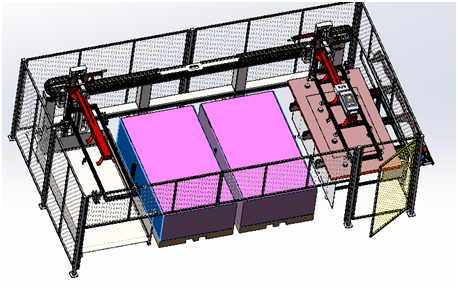

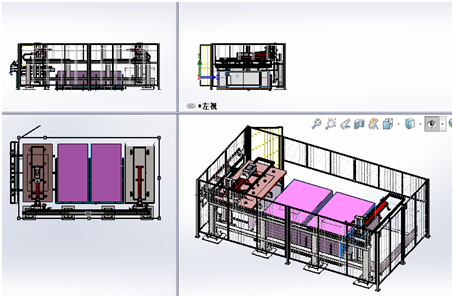

Glass loading machine RO-L7000

Model: RO-L7000

Function description

Move the glass kit to the transmission line

Equipment performance description

Equipment performance

1) Maximum grabbing height 1000mm;

2) The suction cup of the glass carrier is made of polyurethane, which will not leave marks on the glass during the suction process;

3) The whole machine is equipped with a safety fence for safety protection;

4) The equipment is fully automatically controlled and no human operation is required during operation;

5) When grabbing the glass, the cylinder will first pull up one corner of the glass and beat it to separate the glass layers to ensure that the picked glass is a single piece.

Equipment mechanical structure

6) Consists of glass grabbing manipulator and paper picking manipulator;

7) The equipment is driven by servo motor, rack and pinion transmission, and linear guide. It has the advantages of precision and smooth operation.

Motor control structure

8) PLC and servo are connected and communicated through CANopen; improving the stability and high responsiveness of the equipment;

9) The glass loading machine and the assembly line correspond to each other through I/0;

10) The manipulator has a vacuum AMP set limit value lower than the set value and does not operate, sending an ALARM message;

11) The system is composed of PLC+HMI, the operation interface is simple and easy to use, and meets the requirements of modern control;

12) Moving position accuracy is 1~1.5mm.

Equipment technical parameters

Weight:about 1000kg

Working air pressure:0.6~0.8Mpa,φ12 air pipe,350L/min

Power supply:3ψ5W,380V,50/60Hz

Rated load:15kg

Rated power:9KW

Environment: 25±5℃

Humidity: ≤80%

Glass thickness: 1.6-5.0mm

System positioning accuracy: ±1 mm

Tact: according to version

Categories

News

Contact Us

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV