Solar panel production line

100MW solar panel production line 50% automatically

Please watch the video on Youtube:

100MW Solar panel production line

Design 3, 50% Automatically

It is a complete solar panel prodcution line, base on turn-key solution .

Production capacity : 100MW per year ( 1 working shift ) ~ 300 MW per year ( 3 working shift ).

Production speed : 24 pcs solar panel per hour depend on producing 550 w solar panel.

Building space : More than 4000 sqm ( Include office , do not include warehouse ).

Working people : More than 21 persons.

Power consumption : Maximum :300KW, Average.

Investment for machine : Around 1,572,020 USD.

Delivery time : Less than 60 working days .

Service supply : Lay out desigh, Location installation,

Location training, Location trial prodution. After service.

Equipment configuration

1, Solar panel laminator

Video : https://youtu.be/8TBkdLs0EMY

Video : https://youtu.be/8TBkdLs0EMY

USE : As the equipment of manufacturing solar module limited to laminate glass, EVA (Ethylene Vinyl Acetate Sheet), solar cell and back sheet

Dimension : 32000mmx 3380mm x1300mm

Laminating area: 5500mm x 2400mm.

Laminating height: 25mm

Double chamber, First chamber for EVA film melting, Second chamber for EVA solidify .

Total power consumption: 150 KW ( AC380V, 60 Hz, or according to customer's nee)

Air source: 0.6 - 1.0 MPa. 200L/ min .

Operating mode: Manual / Automatic.

Control system : PLC ( Seimens). HIM system: Touch screen ( Seimens )

Heating mode: Oil Heating ( SD320 heat conducting oil, capacity: 170 L, flow pressure:0.3 Mpa.), include: main heating and adjustable heating.

Temperature control: PID intelligent temperature control system.

Temperature uniformity in working area: ≤ ±1.5 ℃

Temperature control accuracy:≤± 1 ℃.

Temperature control range: 30℃ - 180 ℃

Pumping rate: 70 L/s .Laminating time: 2 - 4 min ( excluding solidificationtime )

Heating rate: 140℃ at room temperature with 50 to 60 minutes

Vacuum rate: 200 L / S, the limit vacuum 70 ~ 90 Pa, Vacuum time: 90 seconds

Silicone membrane size:8200mm * 3200mm, 5 mm thickness. The laminating times more than5000 times.

Quick replace silicon membrane design.

Lid opening: Straight from the hydraulic, the biggest opening height: 200 mm

Total weight: 30,000Kg.

Production capacity:

Conventional 550 Wp (2279*1134) solar module, 4 pcs in a cycle time.

Production Capacity:

550 WP *4 pcs/ Cycle * 6 Cycles/h * 8 hours* 300days=31.6 MWp / year.

2, Laser cutting machine More detail

Video : https://youtu.be/4H069kZQk9A

Video : https://youtu.be/4H069kZQk9A

3, Tabbing & string machine More detail

Video : https://youtu.be/cYkpdmTrQik

4, EVA / BACKSHEET cutting machine More detail

Video : https://youtu.be/D3EsR66WwoE

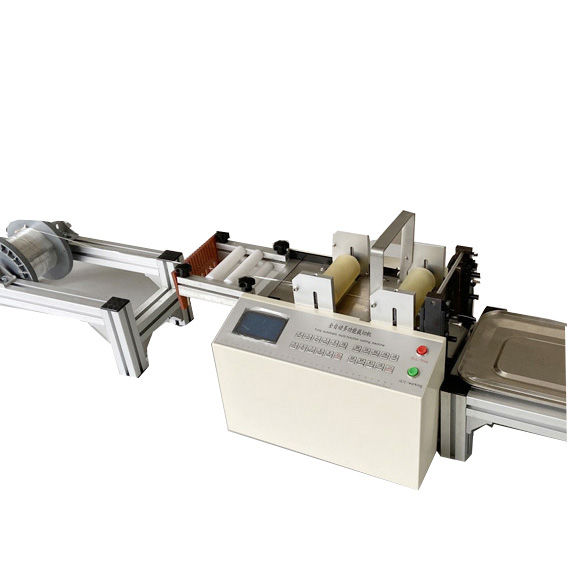

5, Bus bar cutting machine More detail

Video : https://youtu.be/5ZN_ZZEfLYs

Video : https://youtu.be/5ZN_ZZEfLYs

6, Glass loading machine

Loading PV glass by Pneumatic chuck.

Shifting suction cup will absorb the glass from the pallet and put it on the conveying line

The equipment is equipped with double photoelectric switch confirmation, which can avoid the protection of glass collision caused by wrong action

Put the paper between the glass into the isolation box

Automatic warning of material shortage (sound and light)

The feeding area has a protection grating or safety door

With ionic fan for dust blowing glass

Can meet different specifications of glass use

With paper separation recycling function

Meet the 150P (3.2mm) one drag glass size, and 2 torches directly seamless switch.

Working power supply | AC 380V 3 phase 5 wire system 50Hz |

Work pressure | 0.6 ~ 0.7 Mpa |

Power | 5 KW |

Manipulator load | 40Kg |

7, Laying up machine More detail

8, Bussing station

Product features:

1,Manual soldering of all the bus-band of the middle outlet plate of half piece and the welding of the bus-band of the three-outlet assembly at the head of the whole piece of double glass

2, vacuum taking cell stringer

3. The position of 12 and a half cell strings can be corrected twice

4, Manual preparation of folding TYPE L bush bar

Product parameters:

Component input and output height : 950 + 20 mm

The component version : The 156/5BB is standard, and the 10 and 12 string configurations of all cell in 156-170mm sizes are customizable material

Confluence with reel feeding, automatic feeding, cutting, size can be customized .

Power supply equipment: 380 v / 220 v 50/60 hz

Power : Peak 5KW.

Air supply : Pressure 0.5-0.7mpa flow 1.8m³/min

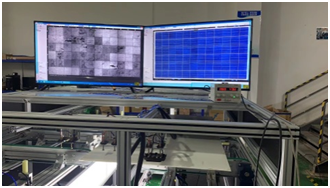

9, EL & VI tester

Electroluminescent inspection for detect solar panel before laminating and after laminating.

To check solar panel of secluded split, cracked cell, rosin joint, wire break and other defects.

Can testing module: 2600mm x 1400mm

Maximum current: 10A,Maximum voltage: 60V

Include:Cabinet(Include infrared camera)+ Computer + Software

4 cameras, take 12 pictures for one solar module , the pixel get 20 million.

Time of exposure:0.1 S-25.5 S Adjustable

Power: 220V 10A or customize.

Working environment temperature :10 - 30 ℃

Humidity: 20 - 70%

Main function of characteristics:

By using images can find: material other defects. the sides of the pneumatic feeding short, art and craft contamination

Testing fast and convenience was longtime 1s - 25s ( adjustable )

It is testing on line.

Power consume : 2 KW

10, Trimming station

Work beat: 20 seconds

Suitable size :Length: 1650-2500 - mm ; width : 990-1400 - mm

The maximum weight: 50Kg

Power supply AC 380V 3-phase 5-wire 380V 50HZ/60HZ

Rated power: 1KW

Working pressure 0.6-0.8 Mpa

The gas consumption of 500 L / min.

The maximum weight of a single device is 1500kg

11, Inspection machine

Turning over for visual inspection solar panel after trimming .

Automatic turning by PLC control .

Be apply to the solar panel 990 x 1890 mm ~ 2600 x 1400mm .

12, Gluing and framing machine

Technical Specification

1, Solar Panel Minimum size 1650X990X50 (35) mm;

2, Solar Panel maximum size 2500X1400X50 (35) mm

3, Compatible with a maximum weight:50kg

4,Rated power: framing machine 13kw,machine hand 5kw

5,Working power: AC 380V 3-phase 5-wire system 380V 50HZ/60HZ

6,Air consumption: Framing machine 800L/min Manipulator 20L/min

7,The maximum weight of a single device: Framing machine 4000kg Manipulator 2000kg

8,Working noise ≤72db

9, Source of compressed air cylinders volume: air Source: 0.6 ~ 0.8 Mpa;

10, PLC program.

11, Auto loading .

12, The heavy screw mechanism makes the frame error very small.

Features of the machine

Strong point , the width dimension can be adjust.

Distinctive allocation is locked up. The multiple spot assists pressure the head handle simple, convenient.

13, JB gluing machine More detail

Video: https://youtu.be/jBdHW68SgOQ

Video: https://youtu.be/jBdHW68SgOQ

14, Gel Injection station

The equipment can meet the requirements of single unit, split junction box, and full coverage of glue filling range

Technical Specification

1, Source of compressed air cylinders volume: air Source: 0.6 ~ 0.8 Mpa;

2,Compatible with a maximum weight: 30Kg

3, Voltage:AC 220V 3-phase 5-wire 50HZ/60HZ

4, Rated power:0.5kw

5, Air consumption:5L/min

15. Unloding machine More detail

16. Solar module tester More detail

Video: https://youtu.be/bwuWdhUHSCY

Video: https://youtu.be/bwuWdhUHSCY

You can Click each above equipments to check the specification detail .

This specification shall cover design, manufacture, shipping, oversea installation,oversea training and oversea after service. This solar panel production line should have a production capacity of 100 MW/year considering 80% uptime and single shift of operation.

Workshop:

1. General requirements of workshop: more than 4000 square meter.

Requirements in warehouse: The soldering room and EVA storehouse temperature, keep in 25 ℃.

2. Infrastructure:

(1) Power source: 3 phase 5 line, more than 300 KW;

(2) Water supply: little need.

(3) Air source: 400L / min compressed air;

(4) Environment: (enclosed, dust-proof, anti-skid, temperature);

(5) The main production site layout plans.

Solar panel produce program

1. Preparation: Preparation of raw materials.

2. Cutting material: EVA. TPT. soldering wire.

3. Soldering solar cell. By tabbing and string machine.

4. Laying up:Tabbing solar cell on the EVA and glass.

5. Laminating: Laminate EVA , Solar cell and back sheet also glass by the laminator..

6. Fix junction box: Trim edge of the extra EVA and fix junction box on the panel.

7. Testing: Test laminated solar panel by EL tester and solar module tester.

8. Quality tests: In the process of making other tests, IV curves of the test, and the appearance of high-voltage isolation.

9. Warehousing: Qualified storage products, goods failed to repair.

The main raw materials

① Tempered glass

② Solar cells

③ EVA film

④ TPT sheet

⑤ Junction Box

⑥ Soldering ribbon.

⑦ Aluminum alloy frame

⑧ Silicon gel

⑨Soldering flux.

⑩ High temperature tape

Layout:

We design the factory layout showing different machines for smooth production. The layout should show the all the machines including the store and office area in proposed layout plan.

Installation:

We send engineer or technicians to buyer’s factory to install machine. All expenditure on travel, food, accommodation and transportation of our engineers/ technicians for installation will be borne by buyer. REOO company borne the salary of engineer/technicians.

Training:

We supply both overseas and local training to the engineers and technicians on operation and maintenance. buyer borne air tickets, lodging, food and training material .

Minimum 12 (twelve) months warranty of all products and services and guarantee for the spares and required maintenance or replacement support are to be provided . Buyer borne the cost of the material for parts of maintenance.

Payment Terms:

40% of the contract value be pay by T/T advanced.

60% before shipment.

Delivery time:

60 days after received the advance payment.

Insurance:

We borne insurance of goods under contract from the time these are loaded on board the ship.

Taxes and Duties:

Buyer shall pay all taxes and duties, payable under government laws, for all goods and materials imported under the contract into any port .

Packing:

All the equipment, tools, accessories and goods be suitably packed. All packages are liable to be opened for customs examination and packing shall therefore be designed to facilitate opening and repacking thereafter. Each package shall have the shipment information printed on it in bold letters.

Manuals/Documents:

Operational and maintenance manuals of all equipment is in English, along with a soft copy in a CD (compatible version: MS Word/ PDF).

Backup spares:

We supply essential backup spares. items beyond warranty periods, buyer borne the cost.

Raw material:

We supply all the material for production solar panel from China for trial production and formal production, buyer pay for the cost.

Power consume:

The total consume for electricity power: 300 KW, 3 Phase , 5 line .

Guarantee and after -sale service:

One year guarantee for whole machine except of consumable..

24 hours technical support by E-mail, Skype or QQ..

Calling or door-to-door service

Ues-friendly English software, user manual and detailed Video/CD.

Categories

News

Contact Us

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV