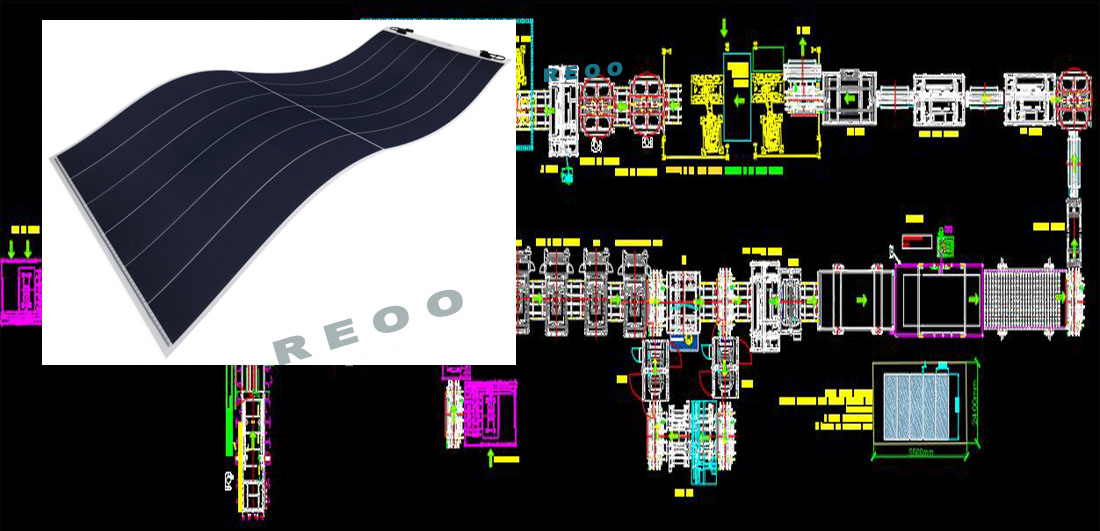

Solar panel production line

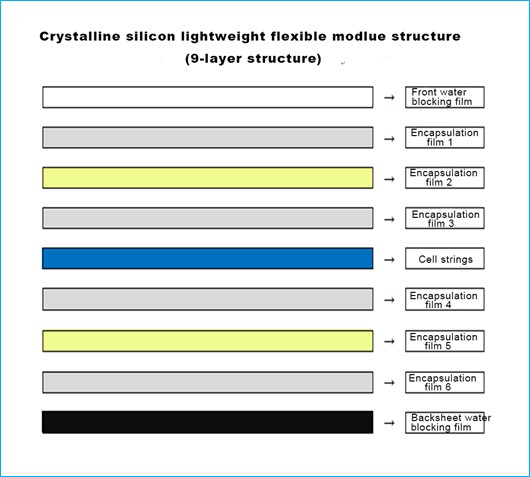

Light-weight Solar panel production line

Lightweight and BIPV module assembly line

Technical proposal

1. Production line specifications

1.1 Basic functional requirements of the equipment and equipment overview. Basic functional requirements of equipment:Assembly line conveying working speed: Before lamination 0-20 m/min/adjustable.(All are frequency-controlled and speed-adjustable, suitable for module products with a load weight of less than 20 kilograms, and have smooth transportation and anti-interference functions, and are compatible with a variety of module sizes.)

1.2 Applicable module size: size is 2054 x 1080mm

1.3 The load-bearing and conveying capacity of a single section of the assembly line is greater than 20KG.

1.4 The online transmission position of modules is accurate, and the positioning repeatability error is ≤10mm.

1.5 Component lamination spacing requirement range: module lamination spacing requirement on each side: 50mm-100mm.

1.6 Rotation positioning accuracy:±0.2deg。

1.7 There is an alignment mechanism before lamination, which is positioned by glass/kit. The positioning accuracy can be controlled within ±5mm. The laminated parts are all in the appropriate position in the laminator cavity, and the repeatability error is ≤5mm.

1.8 The linear profile guide rail connection is straight; the horizontality error of the 5-meter line length is less than ±5mm.

1.9 Straightness: The error of the two-section assembly line is less than ±5mm (horizontal calibration).

1.10 The transmission belt adopts PU synchronous belt (to reduce silicone bonding pollution and prevent belt friction marks on coated glass).

1.11 The sensors equipped on the assembly line also have anti-interference performance.

1.12 The entire conveyor line is on the same horizontal line.

2. Production line layout

Please refer to the CAD production line layout diagram for details.

3. Composition of the final assembly production line (see equipment list for details)

S/N | Equipment name | Main functions |

1 | Cutting ,Tabbing and string machine | Soldering connect the solar cells according to process requirements with EL inspection. |

2 | Glass loading | Load PV glass on conveyor for BIPV panel . |

3 | Glass kit board loading | Automatically load glass and remove paper/ kit boards for lightweight modules |

4 | Conveying/conveying alignment | Module conveying and its position alignment |

5 | Cutting machine | Fully automatic EVA/POE/Backsheet cutting, punching, laying and placement |

6 | Bus bar bussing machine | Solder multiple cell strings together through bus bars |

7 | Assembly line turning | 90 degree turn conveyor, channel |

8 | Laying machine | Automatically place battery strings on glass for layout |

9 | Assembly line turning | 90 degree turn conveyor |

10 | Automatic tape machine | Automatically apply high-temperature transparent tape to secure cell strings to each other |

11 | Buffer | 18 layers buffer, modules are stored and keep the automatic line running normally |

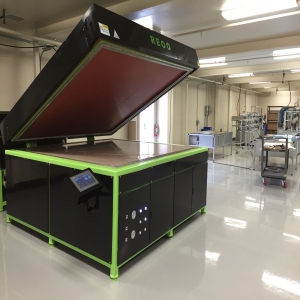

12 | Laminator | Perform vacuuming, lamination, curing, and cooling processes on modules |

13 | Lightweight module trimming | Use an oscillating knife to automatically remove excess material around modules |

14 | Gluing machine | Apply sealant to the junction box pasting surface |

15 | Potting machine | Fill the junction box with sealant |

16 | Conveying line | Convey modules |

17 | Load palletizing machine | Put the modules on the assembly line on the moving curing line |

18 | Curing line | Modules glue curing |

19 | Unload palletizing machine | Grab modules from the curing line to the assembly line |

20 | IV Tester | Test module power |

21 | EL | Check whether the modules have any defects such as cracks or others |

22 | Labeling | Apply module parameter label paper |

23 | Kit board | Support lightweight modules on the assembly line (used in the process before trimming) |

24 | Kit board with convex edges | Support lightweight modules on the assembly line (Used after trimming process) |

4. Production line control and line parts

4.1 Main controller: The entire line uses PLC as the main control (master station);

4.2 Slave station: The branch line uses a module (slave station) to communicate with the master station;

4.3 HMI: And linked to the human-machine interface to conveniently adjust production line parameters;

4.4 Single-machine docking method of production line: dry point docking;

4.5 Conveyor line transmission method: controlled by motor and frequency converter (speed regulator);

4.6 High-precision lifting control method: PLC +servo +photoelectric;

4.7 Equipment structure: aluminum profile + steel structure + sheet metal;

4.8 Overall equipment color: frame body sheet metal white + prompts yellow + danger prompts red (colors can be specified by customers);

4.9 Distribution method of electrical boxes: each station/unit is set individually;

4.10 Electrical wiring method: Laying out high-quality galvanized wiring ducts on the floor。

4.11 The device is equipped with RJ45 network interface, and the communication protocol adopts TCP/iP

5. Production line design specifications

Ⅰ. Capacity: 150 pcs/8 hours

Ⅱ. Number of production line employees: about 9 persons.

Ⅲ. Total power of the production line: about KW; (Updated after the design is finalized, see the secondary configuration table)

Ⅳ. Total air consumption of the production line: m³/min (updated after the design is finalized, see the secondary configuration table)

Ⅴ. Production line power supply requirements:

laminator is three-phase AC 380V, 50HZ/60HZ; Line power supply: single-phase/two-phase AC 220V, 50HZ/60HZ

Ⅵ. Curing line: Length 7 meters

Ⅶ. Laminator specifications: Effective laminating area: 5500*2400mm

6. Specifications of main parts of the equipment

S/N | Project | Brand | Type | Note |

1 | PLC CPU | Inovance | H3U/H5U | |

2 | I/O Module | Inovance | ET- series | |

3 | Frequency converter | Inovance /DELTA | FR-D / FR-E series | |

4 | Area Sensor Safety light shutter | Panasonic/ Shenwu | NA2 series | |

5 | Stepping motor | Leadshine | BMU series | |

6 | AC motor | Zhongda | 220V / 380V 50HZ | |

7 | Servo motor | Inovance /XINJE | MS series | |

8 | Power Supply | MW | DC24V | |

9 | Sensor amplifier | Shenwu/OMRON | NPN | |

10 | Proximity Sensor | Shenwu/OMRON | NPN | |

11 | Photoelectric Sensor | Shenwu/OMRON | NPN | |

12 | Micro Switch | OMRON | NPN | |

13 | Photoelectric Sensor | Shenwu/OMRON | NPN | |

14 | HMI human machine interface | Inovance | Color, 10 inches | |

15 | P.B / Indicator Buttons/indicators | CHNT | NP4 series | |

16 | EMO emergency button | CHNT | LAY3 series | |

17 | Signal tower light | CHNT | MR6-302B series | |

18 | Relay | OMRON | MY*NJ / LY*NJ | |

19 | Medium and large circuit breakers | CHNT | NB8 series | |

20 | Micro Circuit breaker | CHNT | NB8 series | |

21 | Electromagnetic contactor | CHNT | Nc1 series | |

22 | Temperature Controller | 48*48 series | ||

23 | Panel type main power switch | CHNT | HZ12 series | |

24 | Air cylinder brake | AirTAC | Thin cylinder/standard cylinder series | |

25 | Electromagnetic valve | AirTAC | SY series or series with similar functions | |

26 | Air cylinder brake | AirTAC | Thin cylinder/standard cylinder series | |

27 | pressure regulating valve | AirTAC | SY series or series with similar functions | |

28 | Linear slide rail | HIWIN or similar | A series of products that meet design functions and precision | |

29 | Ball guide screw | HIWIN or similar | A series of products that meet design functions and precision | |

30 | Reducer | Zhongda | Meet design function | |

31 | Gear row, gear | Precision helical gear | Meet design function | |

32 | Robot | Inovance | Meet design function |

Categories

News

Contact Us

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV