Solar panel raw material

Soldering liquid flux

X215-T Soldering Flux

Low-Solids, No-Clean Liquid Flux for Photovoltaic Assembly

Product Description

X215-T is a zero-halogen, non-rosin organic flux designed specifically for use in tabber and stringer equipment of Photovoltaic Assembly (PV) module industry by soldering tabs to cell contacts. 952-S could be applied directly to interconnecting ribbon by hand soldering or auto-equipment with tabber and stringer soldering system, by dipping or spraying. The extremely low solids content (around 2%) and nature of the activator system results in practically no residue left on the cell after soldering. Cell are dry and cosmetically clean as they exit the tabber and stringer machine. 952-S has a wider operating window varying with temperature range, and can be used in SnPb, SnAgPb and Pb-free alloys.

Performance Characteristics:

■ Zero-Halogen

■ Produces high reliable ribbon that

interconnects solar cells

■ Wetting and Drying quickly allowing

fast throughput

■ Compatible with the most popular

EVA

■ Can be applied by spraying and

dipping

■ Low-Solids

■ Eliminates cleaning process

■ Leaves less uniform residue to get

higher power transfer efficiencies

■ Classified as ORL0 per J-STD-004

& conforms to Bellcore GR-78

Requirement

Physical Properties

Specific Gravity: 0.803

Anton Paar DMA 35 @ 25°C

Percent Solids (theoretical): 2%

Acid Number (typical): 15.0 mg KOH/g flux

Tested by potentiometric titration

Reliability Properties

Copper Mirror Corrosion: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.3.32

Corrosion Test: Pass

Tested to J-STD-004B, IPC-TM-650, Method 2.6.15

Chloride and Bromides: None Detected

Tested to J-STD-004, IPC-TM-650, Method 2.3.35

Silver Chromate: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.3.33

Fluorides by Spot Test: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.3.35.1

Application Notes

Flux Application

Need to ensure flux is sufficiently applied on the cell to prevent dewetting and residues.

Process Considerations

952-S is engineered for the PV module industry for both automated tabber and stringer application, and hand soldering. Standard pre-heating and heat temperature can be used without special cooling or pre-baking required. Consult your machine supplier or Kester Technical Support for further information.

Cleaning

952-S flux residues are non-conductive, non-corrosive and do not require removal in most applications. If residue removal is required, contact Kester Technical Support for further cleaning recommendation.

Storage and Shelf Life

952-S is flammable. Store away from sources of ignition. Shelf life is 1 year from the date of manufacture when handled properly and stored between 10-25°C (50-77°F).

Health and Safety

This product, during handling or use, may be hazardous to your health or the environment. Read the Safety Data Sheet (SDS) and warning label before using this product.

Categories

News

Contact Us

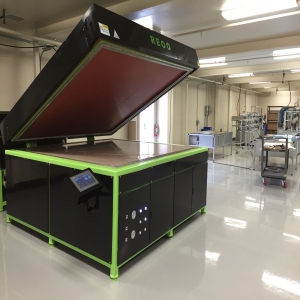

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV