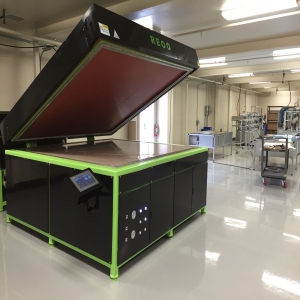

Solar panel production line

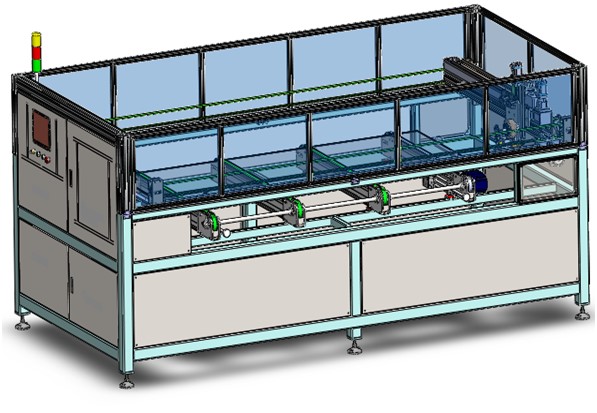

60MW Lightweight Solar Panel Production Line

60MW Lightweight Solar Panel Production Line

It is a complete solar panel prodcution line, base on turn-key solution .

Production capacity : 20MW per year ( 1 working shift ) ~ 60 MW per year ( 3 working shift ).

Automatic level: 85%

Module type: Film-Backsheet module

Max size of solar module: 2054×1080 mm (450W)

Production speed : 150 pcs solar panel pern8 hours depend on producing 450 w solar panel.

Building space : More than 2000 sqm ( Include office , do not include warehouse ).

Working people : More than 9 persons per shift.

Power consumption : Maximum :300KW, Average.

Investment for machine : Around 1,068,000 USD.

Delivery time : Less than 60 working days .

Service supply : Lay out desigh, Location installation,

Location training, Location trial prodution. After service.

Equipment configuration

1. Glass loading machine More detail

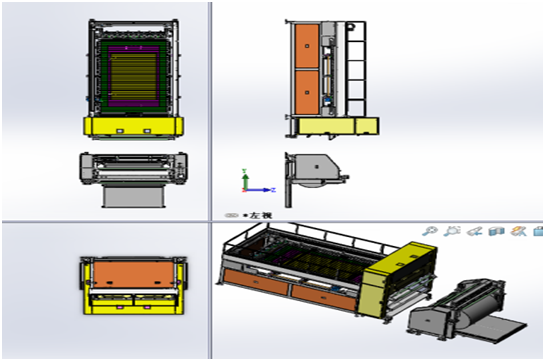

2. Laying machine

Function

1) Transfer the cell strings flowing out of the tabbing and string machine to the laying machine;

2) The typesetting machine performs regular laying according to the polarity and position of the cell string;

3) The long edge of the glass enters and the long edge comes out and has an automatic precision alignment function.

Technical parameters

Weight: 1000KG

Air source: 0.6-0.8Mpa, φ12mm air pipe, 300/Lmin

Power supply: 3ψ5W,380V,50/60Hz

Rated power: 9KW

Rated load: 15kg

Transfer speed: 20m/min

Environment: 25±5℃

Humidity: ≤80% (no condensation)

Tact: According to version

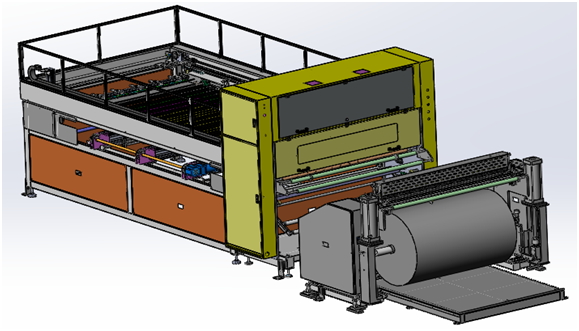

3. Foil cutting machine

Function: Fully automatic EVA/POE/Backsheet cutting, punching, laying and placement

Technical parameters

Weight: about 1300kg

Working air pressure: 0.6-0.8Mpa, φ12mm air pipe

Rated power: 8KW

Air consumption: 500L/min

Power supply: 0--20M/min

Laying accuracy: ±1mm

Cutting knife life cycle: 2 million times

Maximum roll diameter: 400-600mm

Cutting length: 400-2200mm

Maximum cutting width: 1200mm

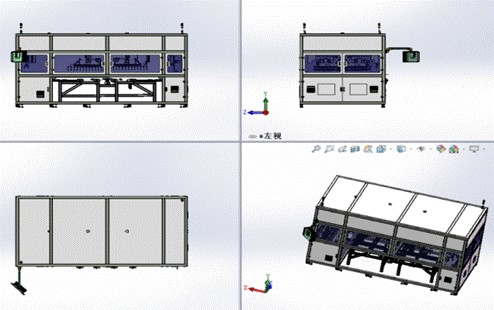

4. Bussing machine

Function

The bus bur uses an electromagnetic heating device to first position and press the bus bar and soldering ribbon. The tin layer on the surface of the soldering strip is then heated and melted through a magnetic field. After the two are combined, they are solidified by cooling air.

Technical parameters

Weight: 3500kg

Air source: 0.6-0.8Mpa, φ16mm air pipe, 1000/Lmin

Power supply: 3ψ5W,380V,50/60Hz

Rated power: 50KW

Rated load: 15kg

Transfer speed: 20m/min

Soldering method: Electromagnetic type

Operation interface: 10-inch touch screen

Environment: 25±5℃

Humidity: ≤80% (no condensation)

Tact: According to version

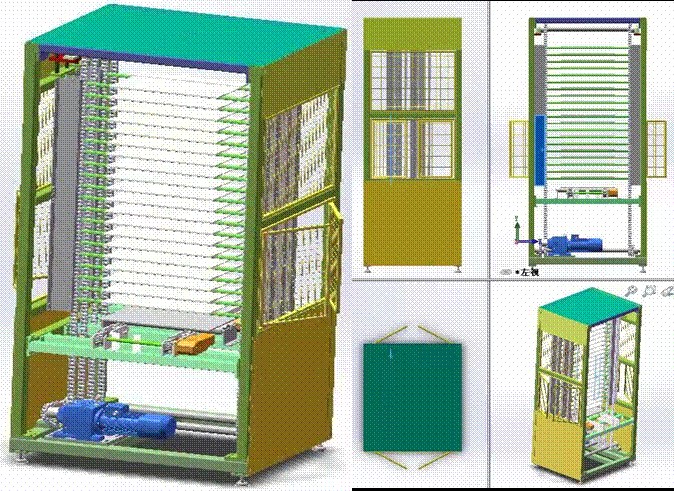

5. Buffer

Function: 18 layers buffer, modules are stored and keep the automatic line running normally.

Technical parameters

Weight: about 500kg

Air source: 0.6-0.8Mpa, Φ8mm air pipe

Power supply: 3ψ5W,380V,50/60Hz

Rated power: 2.5KW

Rated load: 300kg

Transfer speed: 0~20M/min

Environment: 25±5℃

Humidity: ≤80%

Tact: According to version

6 Taping Machine

Function: Automatically apply high-temperature transparent tape to secure cell strings to each other

Technical parameters

Weight: about 1000kg

Air source: 0.6-0.8Mpa, Φ12mm air pipe

Power supply: 1ψ3W,220V,50/60Hz

Air consumption: 1000L/min

Rated power: 9KW

Rated load: 300kg

Transfer speed: 0~20M/min

Environment: 25±5℃

Humidity: ≤75%

Tact: According to version

Tape width size: 10mm

Tape break size: 20mm

Work noise: ≤72dB

Control System: Servo control

Repeat positioning accuracy: +/-1.0mm

Precise pasting accuracy: +/-1.5mm

7. Trimming machine

Function: Use an oscillating knife to automatically remove excess material around modules

Technical parameters

Weight: about 1000kg

Air source: 0.6-0.8Mpa,

Power supply: 1ψ3W,220V,50/60Hz

Rated power: 3.0KW

Rated load: 50kg

Transfer speed: 0~18M/min

Environment: 25±5℃

Humidity: ≤80%

Cutting speed: 0-400mm/s

Repeat accuracy: ±0.05mm

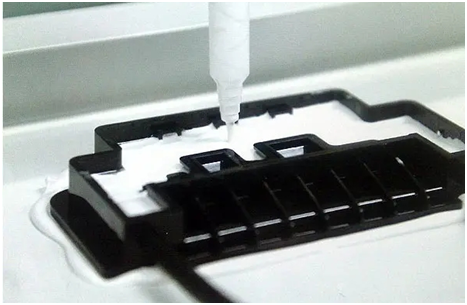

8. Junction box potting machine

Function: Fill the junction box with sealant.

Technical parameters

Air source: 0.6-0.8Mpa, Φ12mm air pipe, 200 L/min

Power supply: AC220V,50Hz

Rated power: 8KW

Proportional accuracy: accuracy ±1.5%

Glue output: >10CC

Tact: According to version

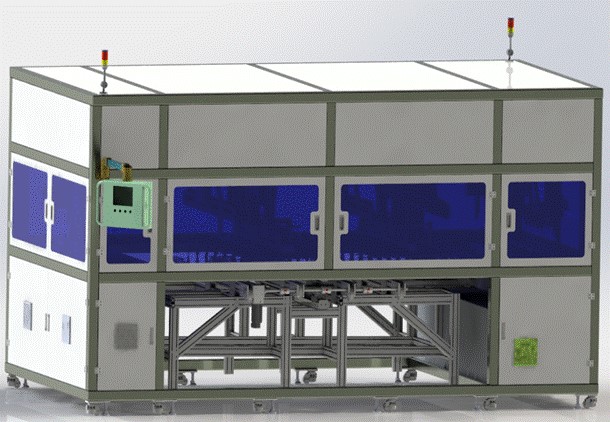

9. EL tester

Function: Check whether the modules have any defects such as cracks or others

Technical parameters

Weight: about 1000kg

Air source: 0.6-0.8Mpa, Φ12mm air pipe, 50L/Min

Power supply: 220V,50Hz

Rated power: 5KW

Transfer speed: 0~20M/min

Environment: 25±10℃

Humidity: ≤80%

Tact: According to version

Number of cameras: 8

Table height: 950mm(±50mm)

Camera type: Single lens reflex

Application Type: Before lamination or after lamination

Resolution ratio: single 6000*4000, full frame 10000*6000(60 million pixels)

Recognition accuracy: < 0.5mm/pixel(EL)

10. IV tester

Function: Test module power.

Technical parameters

Air source: 0.6-0.8Mpa, Φ12mm air pipe, 50L/min

Power supply: AC220V,50Hz

Rated power: 8KW

Environment: 25±10℃

Humidity: ≤85%

Calibration method: Standard modules automatically calibrate light intensity in a single time

Illuminance non-uniformity: <2%(A grade)

Spectral range: 400-1100nm

Flash time: Standard pulse width

Irradiance range: 1000W/m²

Repeatable measurement accuracy: <±1%

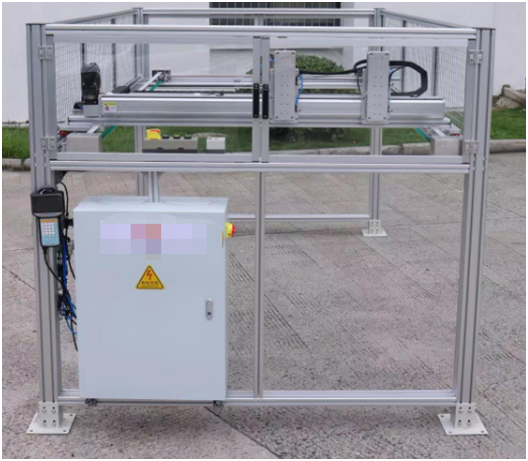

11. Curing line loading/unloading machine

Function: Put the modules on the assembly line on the moving curing line. Grab modules from the curing line to the assembly line.

Technical parameters

Air source: 0.6-0.8Mpa, Φ8mm air pipe

Air consumption: 350L/min

Power supply: 3ψ5W,AC380V,50Hz

Working noise: ≤72db

Rated power: 8KW

Humidity: ≤85%RH

Tact: According to version

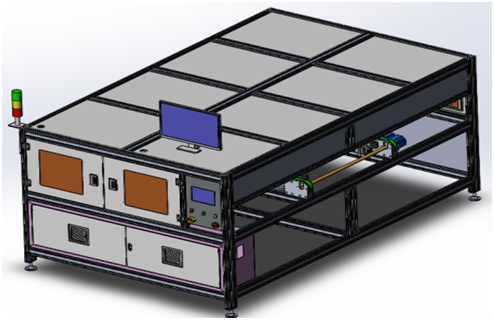

12. Curing line

Function: Modules glue curing.

Technical parameters

Air source: 0.6-0.8Mpa

Power supply: 3ψ5W,AC380V,50Hz

Rated power: 3KW(Varies depending on overall length)

Working noise: ≤72db

Humidity: ≤85% RH

You can Click each above equipments to check the specification detail .

This specification shall cover design, manufacture, shipping, oversea installation,oversea training and oversea after service. This solar panel production line should have a production capacity of 60 MW/year.

Workshop:

1. General requirements of workshop: more than 4000 square meter.

Requirements in warehouse: The soldering room and EVA storehouse temperature, keep in 25 ℃.

2. Infrastructure:

(1) Power source: 3 phase 5 line, more than 300 KW;

(2) Water supply: little need.

(3) Air source: 200L / min compressed air;

(4) Environment: (enclosed, dust-proof, anti-skid, temperature);

(5) The main production site layout plans.

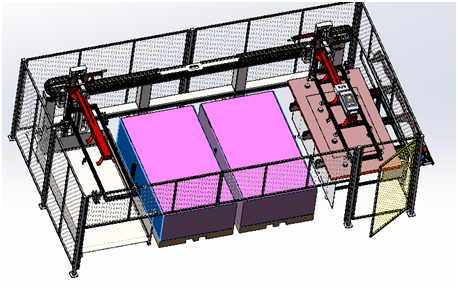

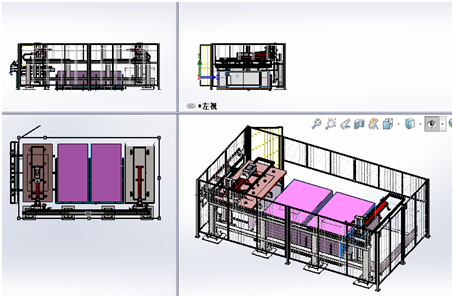

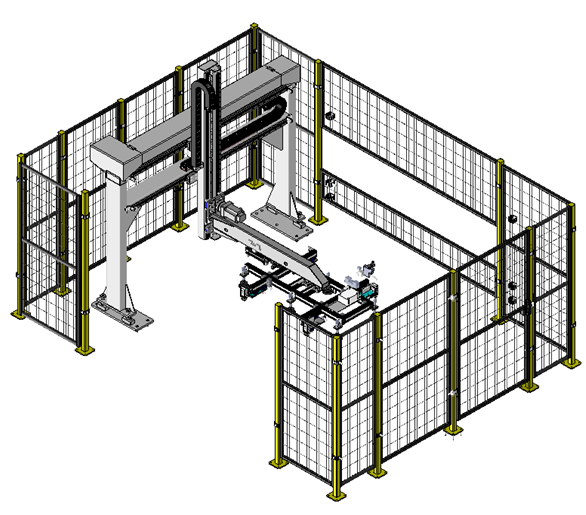

Layout:

We design the factory layout showing different machines for smooth production. The layout should show the all the machines including the store and office area in proposed layout plan.

Installation:

We send engineer or technicians to buyer’s factory to install machine. All expenditure on travel, food, accommodation and transportation of our engineers/ technicians for installation will be borne by buyer. REOO company borne the salary of engineer/technicians.

Training:

We supply both overseas and local training to the engineers and technicians on operation and maintenance. buyer borne air tickets, lodging, food and training material .

Minimum 12 (twelve) months warranty of all products and services and guarantee for the spares and required maintenance or replacement support are to be provided . Buyer borne the cost of the material for parts of maintenance.

Payment Terms:

40% of the contract value be pay by T/T advanced.

60% before shipment.

Delivery time:

60 days after received the advance payment.

Insurance:

We borne insurance of goods under contract from the time these are loaded on board the ship.

Taxes and Duties:

Buyer shall pay all taxes and duties, payable under government laws, for all goods and materials imported under the contract into any port .

Packing:

All the equipment, tools, accessories and goods be suitably packed. All packages are liable to be opened for customs examination and packing shall therefore be designed to facilitate opening and repacking thereafter. Each package shall have the shipment information printed on it in bold letters.

Manuals/Documents:

Operational and maintenance manuals of all equipment is in English, along with a soft copy in a CD (compatible version: MS Word/ PDF).

Backup spares:

We supply essential backup spares. items beyond warranty periods, buyer borne the cost.

Raw material:

We supply all the material for production solar panel from China for trial production and formal production, buyer pay for the cost.

Power consume:

The total consume for electricity power: 300 KW, 3 Phase , 5 line .

Guarantee and after -sale service:

One year guarantee for whole machine except of consumable..

24 hours technical support by E-mail, Skype or QQ..

Calling or door-to-door service

Ues-friendly English software, user manual and detailed Video/CD.

Categories

News

Contact Us

Contact: REOO Tech

Phone: +8613773694841

Tel: +8651384105505

E-mail: mike@reoo.net

Add: Chennan industrial park, Rudong, Jiangsu, China 226400

WhatsApp: + 86 1390 1472 859

Skype: reoochina

Facebook: REOO tech

Twitte: REOO solar PV